-

Table of Contents

“CBD Oil: From Plant to Product, Discover the Journey and Its Impact”

SALE: Buy Premium CBD Gummies!

Each delicious gummy is infused with high-quality CBD to help alleviate pain, reduce stress, and enhance your mental well-being. Perfect for those seeking a natural way to unwind and support overall health.

Buy NowCBD oil, derived from the cannabis plant, has garnered significant attention for its potential therapeutic benefits. The production of CBD oil involves extracting cannabidiol (CBD) from the plant, typically using methods such as CO2 extraction, ethanol extraction, or oil infusion. CO2 extraction is considered the gold standard, as it ensures a pure and potent product by using pressurized carbon dioxide to pull CBD and other beneficial compounds from the plant material. Ethanol extraction, on the other hand, uses high-proof alcohol to dissolve the plant’s compounds, while oil infusion involves heating the plant material in a carrier oil. The resulting CBD oil can be used in various forms, including tinctures, capsules, and topicals. Its significance lies in its potential to alleviate symptoms of anxiety, chronic pain, and epilepsy, among other conditions, making it a valuable addition to the realm of natural health remedies.

Extraction Methods: The Science Behind CBD Oil Production

SALE: Buy Premium CBD Gummies!

Each delicious gummy is infused with high-quality CBD to help alleviate pain, reduce stress, and enhance your mental well-being. Perfect for those seeking a natural way to unwind and support overall health.

Buy NowCBD oil has garnered significant attention for its potential therapeutic benefits, but understanding how it is made is crucial to appreciating its value. The extraction methods used to produce CBD oil are pivotal in determining its quality, efficacy, and safety. These methods are rooted in science and involve intricate processes that ensure the final product is both potent and pure.

SALE: Buy Premium CBD Gummies!

Each delicious gummy is infused with high-quality CBD to help alleviate pain, reduce stress, and enhance your mental well-being. Perfect for those seeking a natural way to unwind and support overall health.

Buy NowOne of the most common extraction methods is CO2 extraction, which is revered for its precision and safety. This method utilizes carbon dioxide under high pressure and low temperatures to isolate, preserve, and maintain the purity of the CBD oil. The process begins by placing the CO2 in a chamber where it is subjected to high pressure until it becomes a supercritical fluid, a state that allows it to act as both a gas and a liquid. This supercritical CO2 is then passed through the cannabis plant material, extracting the cannabinoids, terpenes, and other essential compounds. The result is a high-quality CBD oil that is free from harmful solvents and contaminants.

Another widely used method is ethanol extraction, which involves using high-grade grain alcohol to extract CBD from the cannabis plant. This method is praised for its efficiency and ability to produce a full-spectrum extract, meaning it retains a wide range of cannabinoids and terpenes that work synergistically to enhance the oil’s therapeutic effects. The process starts by soaking the plant material in ethanol, which dissolves the cannabinoids and other compounds. The mixture is then filtered and the ethanol is evaporated, leaving behind a concentrated CBD oil. While effective, this method requires careful handling to ensure that no residual solvents remain in the final product.

SALE: Buy Premium CBD Gummies!

Each delicious gummy is infused with high-quality CBD to help alleviate pain, reduce stress, and enhance your mental well-being. Perfect for those seeking a natural way to unwind and support overall health.

Buy NowIn addition to CO2 and ethanol extraction, there are also methods like oil infusion and hydrocarbon extraction. Oil infusion is one of the oldest techniques and involves heating the cannabis plant in a carrier oil, such as olive or coconut oil, to extract the cannabinoids. This method is simple and safe but often results in a less concentrated product. Hydrocarbon extraction, on the other hand, uses solvents like butane or propane to extract CBD. While this method can produce a highly potent oil, it carries risks due to the flammability of the solvents and the potential for residual solvent contamination.

The choice of extraction method has significant implications for the quality and safety of the CBD oil. CO2 extraction is often considered the gold standard due to its ability to produce a clean, potent product without the use of harmful chemicals. Ethanol extraction, while effective, requires rigorous testing to ensure no residual solvents are present. Oil infusion is safe but less efficient, and hydrocarbon extraction, though potent, poses safety concerns.

Understanding these extraction methods is essential for consumers who seek high-quality CBD oil. The method used can affect not only the potency and purity of the oil but also its safety and overall therapeutic potential. As the demand for CBD oil continues to grow, it is crucial for consumers to be informed about how their products are made. By choosing CBD oil produced through safe and effective extraction methods, consumers can ensure they are getting a product that is both beneficial and trustworthy.

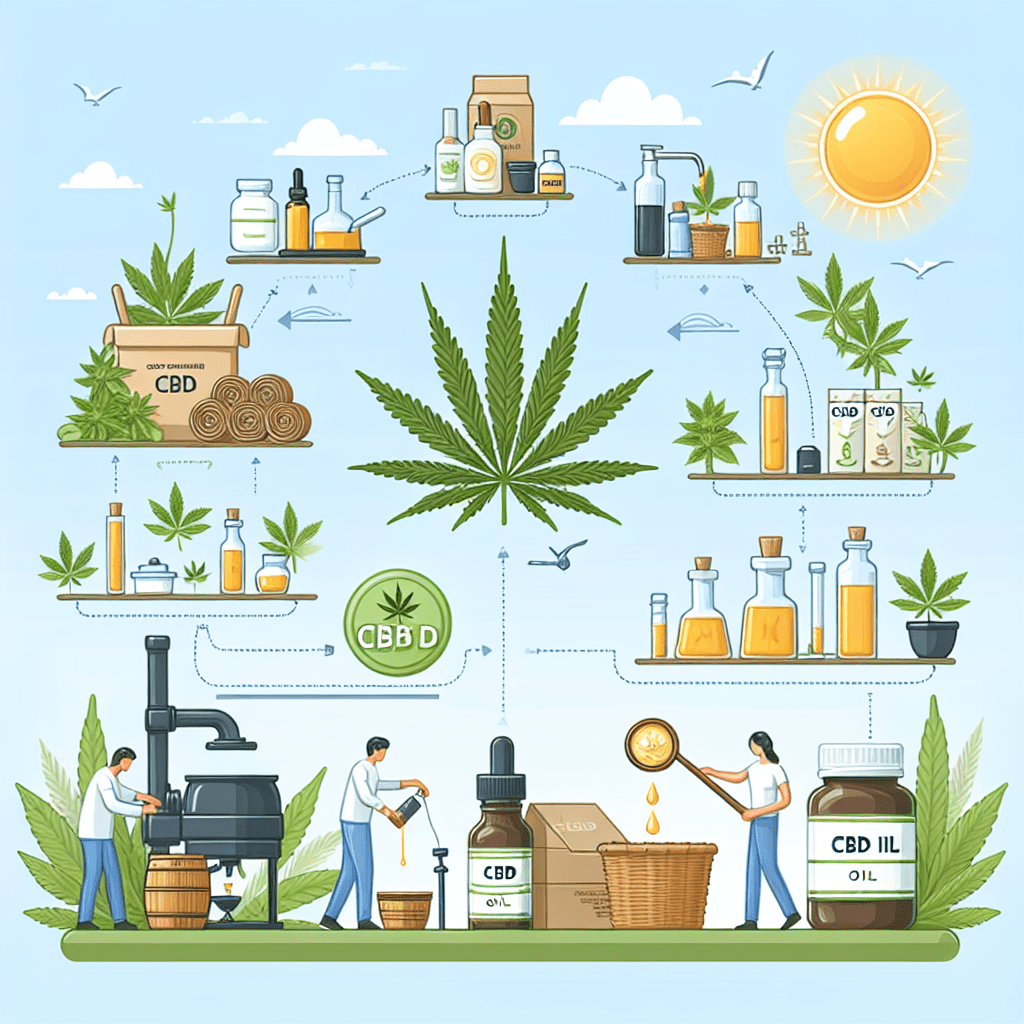

From Plant to Product: The Journey of CBD Oil

CBD oil has garnered significant attention in recent years, not only for its potential health benefits but also for the intricate process involved in its production. Understanding how CBD oil is made, from the cultivation of the hemp plant to the final product, sheds light on why this natural remedy has become a staple in many households.

The journey of CBD oil begins with the cultivation of hemp, a variety of the Cannabis sativa plant species. Unlike its cousin marijuana, hemp contains low levels of THC, the psychoactive compound responsible for the “high” sensation. Instead, hemp is rich in cannabidiol (CBD), a non-psychoactive compound that has been linked to various therapeutic effects. Farmers meticulously select hemp strains that are high in CBD and cultivate them under strict conditions to ensure the plants thrive without the use of harmful pesticides or chemicals.

Once the hemp plants reach maturity, they are harvested and dried. The drying process is crucial as it preserves the plant’s valuable cannabinoids and terpenes. After drying, the hemp is ground into a fine powder, which is then ready for the extraction process. There are several methods to extract CBD from hemp, but the most common and effective technique is CO2 extraction. This method uses pressurized carbon dioxide to pull CBD and other beneficial compounds from the plant material. The result is a pure, high-quality CBD oil that is free from contaminants.

Following extraction, the raw CBD oil undergoes a process known as winterization. This step involves mixing the oil with alcohol and freezing it to remove any remaining impurities, such as fats and waxes. The mixture is then filtered, and the alcohol is evaporated, leaving behind a refined CBD oil. To ensure the highest quality, the oil is often subjected to further purification processes, such as distillation, which separates the CBD from other cannabinoids and compounds.

The final step in the journey of CBD oil is third-party testing. Reputable manufacturers send their products to independent laboratories to verify the potency and purity of the CBD oil. These tests check for the presence of any harmful substances, such as heavy metals, pesticides, and residual solvents. The results are typically made available to consumers, providing transparency and peace of mind.

The meticulous process of producing CBD oil underscores its significance in the wellness industry. CBD oil has been praised for its potential to alleviate a variety of ailments, including chronic pain, anxiety, and insomnia. Its anti-inflammatory properties make it a popular choice for individuals seeking natural alternatives to traditional medications. Moreover, CBD oil is available in various forms, such as tinctures, capsules, and topical creams, allowing users to choose the method that best suits their needs.

In addition to its health benefits, the production of CBD oil also has broader implications. The hemp industry has the potential to boost local economies by creating jobs and supporting sustainable farming practices. Hemp is a versatile crop that requires minimal water and can be grown without synthetic fertilizers, making it an environmentally friendly option.

In conclusion, the journey of CBD oil from plant to product is a testament to the dedication and precision required to produce this natural remedy. As more people turn to CBD oil for its potential health benefits, understanding the meticulous process behind its production highlights why it matters. The combination of rigorous cultivation, careful extraction, and thorough testing ensures that consumers receive a high-quality product that can support their well-being in a natural and effective way.

Purity and Potency: Why Extraction Techniques Matter

The burgeoning interest in CBD oil has led to a surge in products flooding the market, each claiming to offer the best benefits. However, not all CBD oils are created equal, and the extraction techniques used play a crucial role in determining the purity and potency of the final product. Understanding these methods is essential for consumers who seek the therapeutic benefits of CBD without compromising on quality.

One of the most common extraction methods is CO2 extraction, which is often lauded for its ability to produce high-quality CBD oil. This technique involves using carbon dioxide under high pressure and extremely low temperatures to isolate, preserve, and maintain the purity of the oil. The result is a clean, potent product free from harmful solvents. This method is particularly favored by those who prioritize purity, as it minimizes the risk of contamination and ensures that the CBD oil retains its beneficial properties.

In contrast, solvent extraction, which uses substances like ethanol, butane, or propane, is another widely used method. While it is generally more cost-effective, it comes with its own set of challenges. Solvent extraction can leave behind residual chemicals, which may compromise the purity of the CBD oil. Moreover, the process can sometimes degrade the cannabinoids and terpenes, reducing the overall potency of the product. Despite these drawbacks, some manufacturers opt for this method due to its efficiency and lower production costs.

Another technique gaining traction is olive oil extraction. This method is considered one of the safest and simplest ways to extract CBD oil. It involves heating the plant material to activate the cannabinoids and then using olive oil to extract the compounds. While this method is free from harmful solvents and chemicals, it does have its limitations. The resulting CBD oil is less concentrated, meaning consumers may need to use more of the product to achieve the desired effects. Additionally, olive oil extraction has a shorter shelf life compared to other methods, which can be a drawback for those looking for long-term storage.

The choice of extraction method has a direct impact on the purity and potency of CBD oil, which in turn affects its efficacy. High-quality CBD oil should be free from contaminants and rich in cannabinoids and terpenes, the compounds responsible for its therapeutic effects. Consumers should be aware that lower-quality extraction methods can result in products that are less effective and potentially harmful.

Furthermore, the importance of third-party testing cannot be overstated. Reputable manufacturers will often subject their products to rigorous testing to ensure that they meet high standards of purity and potency. These tests can detect the presence of residual solvents, heavy metals, and other contaminants, providing consumers with peace of mind. Transparency in labeling and the availability of lab reports are indicators of a trustworthy product.

In conclusion, the extraction technique used to produce CBD oil is a critical factor that determines its quality. While CO2 extraction is often considered the gold standard for its ability to produce pure and potent oil, other methods like solvent and olive oil extraction have their own merits and drawbacks. Consumers must be diligent in researching and choosing products that prioritize purity and potency, supported by third-party testing and transparent labeling. By understanding the nuances of extraction techniques, individuals can make informed decisions and fully benefit from the therapeutic potential of CBD oil.

The Environmental Impact of CBD Oil Production

The production of CBD oil has garnered significant attention in recent years, not only for its potential health benefits but also for its environmental impact. As the demand for CBD oil continues to rise, it is crucial to examine the ecological footprint of its production processes. Understanding the environmental implications can help consumers make informed choices and encourage the industry to adopt more sustainable practices.

To begin with, the cultivation of hemp, the primary source of CBD oil, plays a pivotal role in determining the environmental impact. Hemp is often lauded for its ability to grow quickly and its relatively low need for pesticides and herbicides compared to other crops. This characteristic can lead to a reduction in chemical runoff, which is beneficial for surrounding ecosystems. However, the environmental benefits of hemp cultivation can be offset by the methods used in large-scale farming operations. For instance, monoculture practices, where a single crop is grown extensively, can deplete soil nutrients and reduce biodiversity. Additionally, the use of synthetic fertilizers, even in hemp farming, can contribute to soil degradation and water pollution.

Transitioning from cultivation to extraction, the process of obtaining CBD oil from hemp plants also has environmental ramifications. There are several methods of extraction, including CO2 extraction, ethanol extraction, and oil infusion. CO2 extraction is often considered the most environmentally friendly option because it uses carbon dioxide, a naturally occurring gas, and leaves no harmful residues. However, this method requires significant energy input, which can contribute to carbon emissions if the energy is sourced from fossil fuels. On the other hand, ethanol extraction, while effective, involves the use of solvents that can be harmful if not properly managed. The disposal of these solvents poses a risk to both the environment and human health.

Moreover, the packaging and distribution of CBD oil further contribute to its environmental footprint. The use of plastic bottles and excessive packaging materials can lead to increased waste and pollution. Companies that prioritize sustainable packaging, such as using recyclable or biodegradable materials, can significantly reduce their environmental impact. Additionally, the carbon footprint associated with the transportation of CBD oil products, especially when sourced from distant locations, cannot be overlooked. Local sourcing and distribution can help mitigate these effects by reducing the distance products need to travel.

Furthermore, the regulatory landscape surrounding CBD oil production also influences its environmental impact. In regions where stringent environmental regulations are in place, producers are often required to adhere to practices that minimize ecological harm. Conversely, in areas with lax regulations, there may be fewer incentives for producers to adopt sustainable methods. Advocacy for stronger environmental policies and consumer demand for eco-friendly products can drive the industry towards more sustainable practices.

In conclusion, while CBD oil offers numerous potential benefits, it is essential to consider the environmental impact of its production. From cultivation to extraction, packaging, and distribution, each stage of the process has implications for the environment. By understanding these impacts and advocating for sustainable practices, consumers and producers alike can contribute to a more environmentally responsible CBD oil industry. As the market continues to grow, the choices made today will shape the ecological footprint of CBD oil production for years to come.